Items & Tools

ITEMS

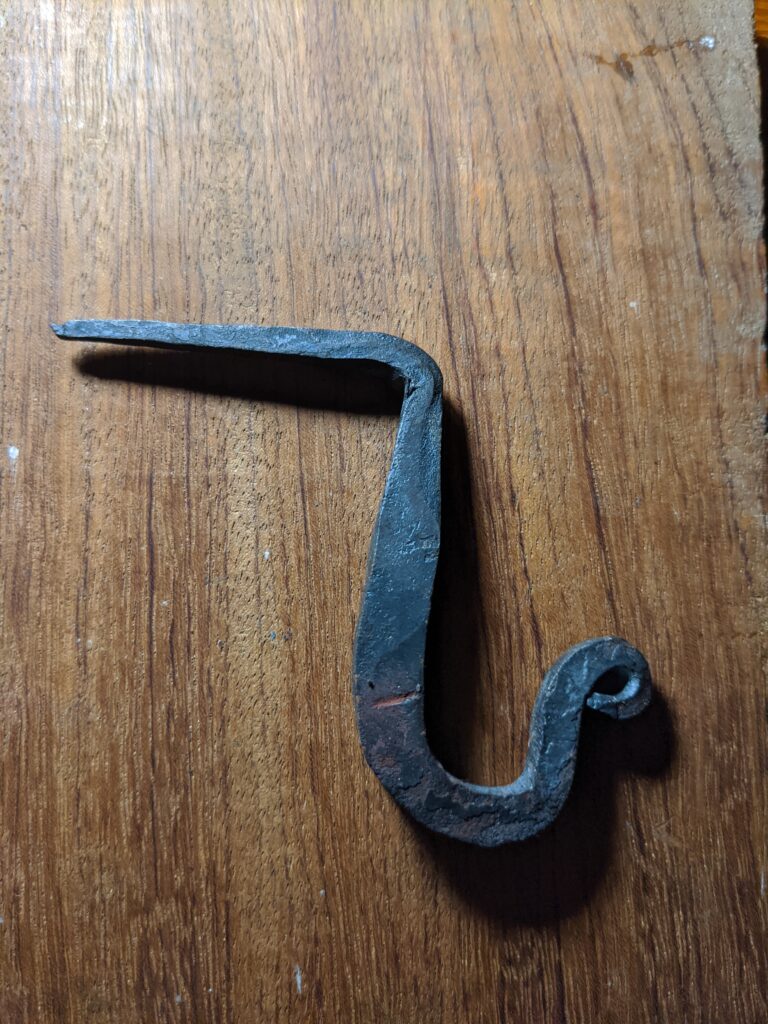

Hooks

Common in any household, they can be used to hang & support a variety of objects. They can be hammered, screwed in, or hung on another hook, with the s hook or double hook.

decorative hooks can also be made using a CnC plasma cutter, which i do not currently own.

Pins & Picks

commonly carried & used for anything from untying knots & punching holes, to holding up hair & as a stylus for scribe work.

while both are built to be sturdy under common use, picks, especially those meant for heavy work, may be hardened & tempered depending on the steel. some are low carbon & have to be quenched in water or brine to fully harden, because of this they may not need a temper.

TOOLS

Arc Welder

A simple buzz box can get every standard welding job done, it runs on 240V AC if i buy the right adapter i should be able to bring the generator and weld on remote job sites.

i am also looking into getting copper coated carbon rod, to see if i can make a small electric arc furnace inside an insulated crucible.

Torch work

Oxy/fuel torches are very important in the shop. These can heat, cut and weld steel in almost any position. My current setup is Oxy/Propane, it is only suitable for heating & cutting steel.

metallurgy

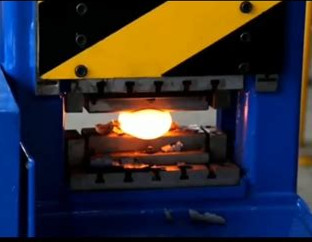

My goal is to make high quality crucible steel. Silicon spring steel alloys of varying composition can be arranged into billets that are forge welded together, then drawn out into long bars with a hydraulic press. These bars can be fully heated and quenched; but, depending on the construction of the billet, the bars can be differentially hardened while retaining the flexible properties of silicon alloy spring steel. This method is ideal for making strong swords, something that i have always wanted to do but have had trouble trying to do so until now. I am not quite there just yet but soon.

To feed the crucibles, I need clean pure iron. To do that, I need a Bessemer converter, or its refined version.

Basic oxygen steel-making. this process uses pure oxygen and fluxes–such as calcium oxide which are chemical bases–to thoroughly clean the raw iron.

Metal Movers

Another goal is to to build a hydraulic press. It is required for moving large ingots of steel, it can also be used for drop forging.

Current methods are a sledge hammer & another person.

A power hammer is also on the acquisition list. Less powerful and more accurate than the hydraulic press, it is more suited for general smithing work, if i had one i would use it most for drawing steel out, a very long & exhausting process. this would allow me to have more energy to focus on the finer details.

cnC plasma cutter

Cheaper than a water jet or laser cutter, a plasma cutter is the best way to precisely cut shapes into sheet steel. It is also on the acquisition list, owning one would allow me to greatly increase product inventory, while keeping each product the same as the last.

Current methods are angle grinder, jigsaw, and oxy/propane torch.

Forge Your Future

This shop is constantly evolving as I learn new methods to offer a wider variety of services. The goal is to experiment and see what I can do with the craft.